🧪 Enzymes in Pharmaceutical Synthesis

Toward Greener, Smarter, and More Efficient Drug Manufacturing

🔬Introduction

Enzymes are nature’s highly efficient and selective catalysts that accelerate biochemical reactions under mild and environmentally friendly conditions. Their application in pharmaceutical synthesis has greatly improved the production of active pharmaceutical ingredients (APIs), intermediates, and complex bioactive molecules. Enzymatic processes offer a sustainable and precise alternative to traditional chemical synthesis methods, which often require harsh reagents, elevated temperatures, and generate unwanted by-products.

This page explores the importance of enzymes in pharmaceutical manufacturing, detailing their types, functions, and recent technological advances that are shaping modern synthesis strategies.

⚗️Advantages of Enzymatic Synthesis in Pharmaceuticals

- Exceptional Selectivity: Enzymes provide regio-, chemo-, and stereoselective catalysis, which is essential for producing pure and effective pharmaceutical compounds.

- Mild Operational Conditions: Most enzymatic reactions occur near room temperature, atmospheric pressure, and neutral pH, preserving sensitive molecular structures.

- Eco-friendly Processes: The use of enzymes reduces hazardous waste and minimizes the need for toxic solvents or reagents.

- Cost-effectiveness: Enhanced specificity limits side reactions and reduces purification costs, improving overall process efficiency.

🌡️Classes of Enzymes Commonly Used

Hydrolases

Catalyze bond cleavage by hydrolysis and are widely employed for selective modification and resolution of chiral molecules.

- Lipases: Useful for esterification and kinetic resolution in the synthesis of complex molecules.

- Proteases: Facilitate peptide bond formation and selective cleavage in peptide-based therapeutics.

- Esterases and Amidases: Employed for selective hydrolysis steps in multi-functionalized compounds.

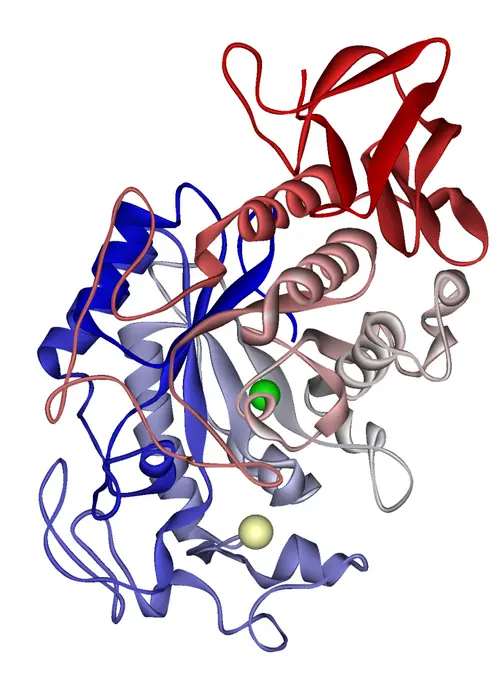

Oxidoreductases

Responsible for oxidation-reduction reactions critical in modifying functional groups.

- Alcohol Dehydrogenases: Enable stereoselective reductions, producing chiral alcohol intermediates.

- Monooxygenases: Allow selective hydroxylation of otherwise inert C–H bonds.

- Peroxidases and Laccases: Facilitate oxidative coupling and polymerization reactions.

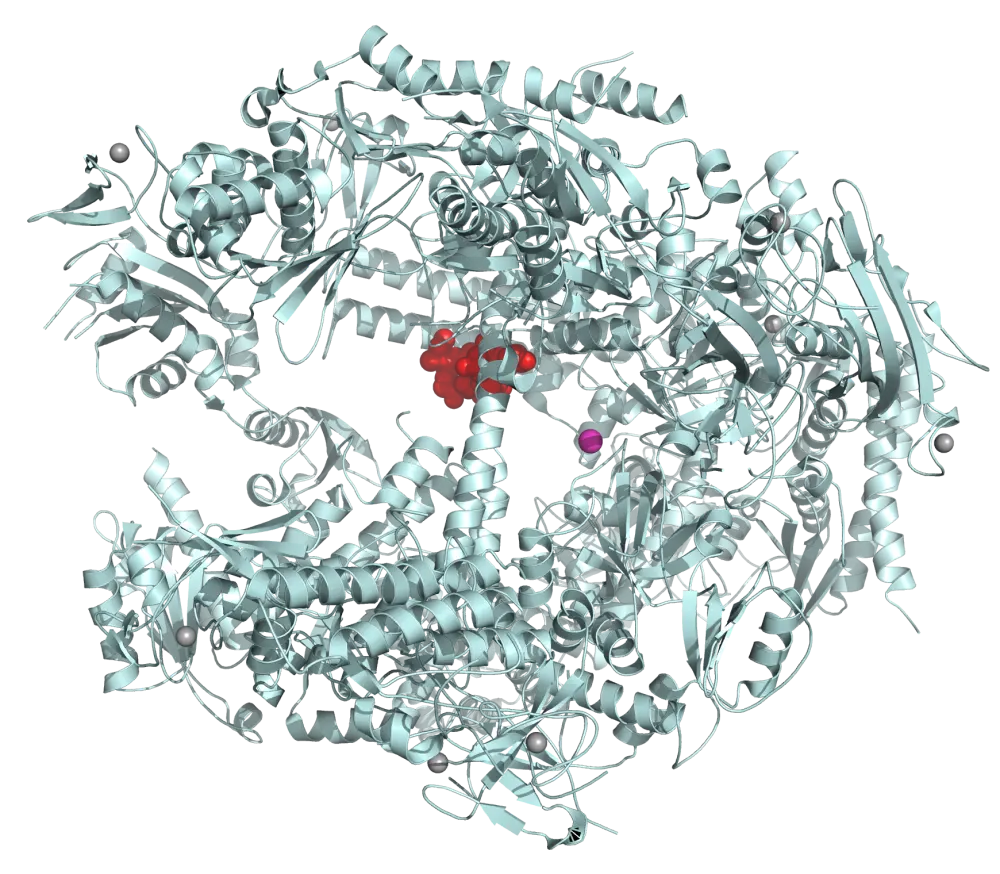

Transferases

Mediate transfer of functional groups, aiding bond formation essential for molecular complexity.

- Transaminases: Catalyze amination, providing chiral amines with high selectivity.

- Glycosyltransferases: Attach sugar groups, enhancing solubility and bioavailability of pharmaceutical molecules.

🧬 Applications in Pharmaceutical Manufacturing

Synthesis of Chiral Intermediates

Chirality is crucial for the biological activity of many pharmaceutical molecules. Enzymes enable:

- Kinetic Resolution: Selective conversion of one enantiomer from racemic mixtures.

- Asymmetric Synthesis: Direct creation of a single enantiomer from non-chiral precursors.

For example, transaminase enzymes are employed industrially for the stereoselective production of chiral amines used as key pharmaceutical building blocks.

Peptide and Protein-Based Compound Production

Proteases and ligases are instrumental in synthesizing and modifying peptides and proteins, yielding high purity materials for therapeutic applications.

Late-Stage Functionalization

Enzymatic methods provide highly selective transformations of complex molecules, facilitating the generation of analogs for screening and optimization.

🧠 Technological Advances

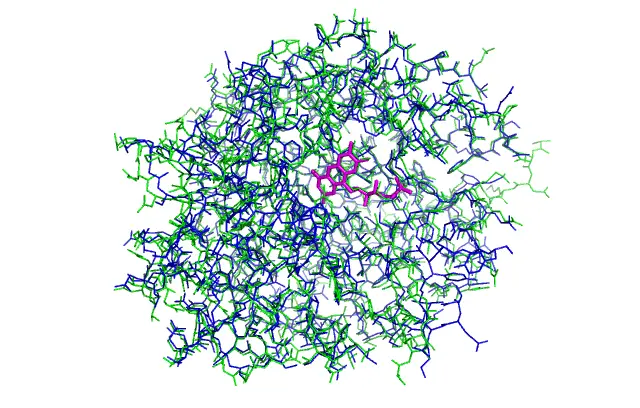

- Directed Evolution: Tailoring enzymes with improved stability, activity, and substrate tolerance.

- Immobilization Techniques: Enhancing enzyme reuse and integration in continuous flow processes.

- Chemoenzymatic Cascades: Combining chemical and enzymatic steps in single-pot reactions to increase efficiency.

- Whole-Cell Biocatalysis: Using genetically engineered microorganisms to perform multi-step transformations with cofactor regeneration.

🌍 Challenges and Future Outlook

Despite significant progress, challenges such as limited substrate scope, scale-up difficulties, and regulatory requirements remain. However, advances in enzyme engineering, synthetic biology, and process development continue to expand the role of enzymes in pharmaceutical manufacturing.

The future holds promise for more sustainable, cost-effective, and innovative enzymatic solutions to meet the growing demand for complex and diverse pharmaceutical compounds.

Enzymes have become indispensable tools in pharmaceutical synthesis, enabling highly selective, sustainable, and efficient production of bioactive compounds. Their continued development and integration will drive innovation and eco-friendly practices in pharmaceutical manufacturing.